In a world where robots are no longer just the stuff of sci-fi movies, robotic automation manufacturing is taking center stage. Imagine a factory floor where machines do the heavy lifting, leaving humans to sip coffee and strategize their next big idea. It’s not just a dream; it’s the future of production, and it’s happening right now.

As industries scramble to keep up with demand, these mechanical marvels are stepping in to boost efficiency and precision. They work tirelessly, never complain about overtime, and don’t need bathroom breaks—talk about a win-win! By embracing robotic automation, companies can streamline processes, cut costs, and even reduce errors. So buckle up, because the age of robots is here, and it’s about to revolutionize manufacturing as we know it.

Robotic Automation Manufacturing

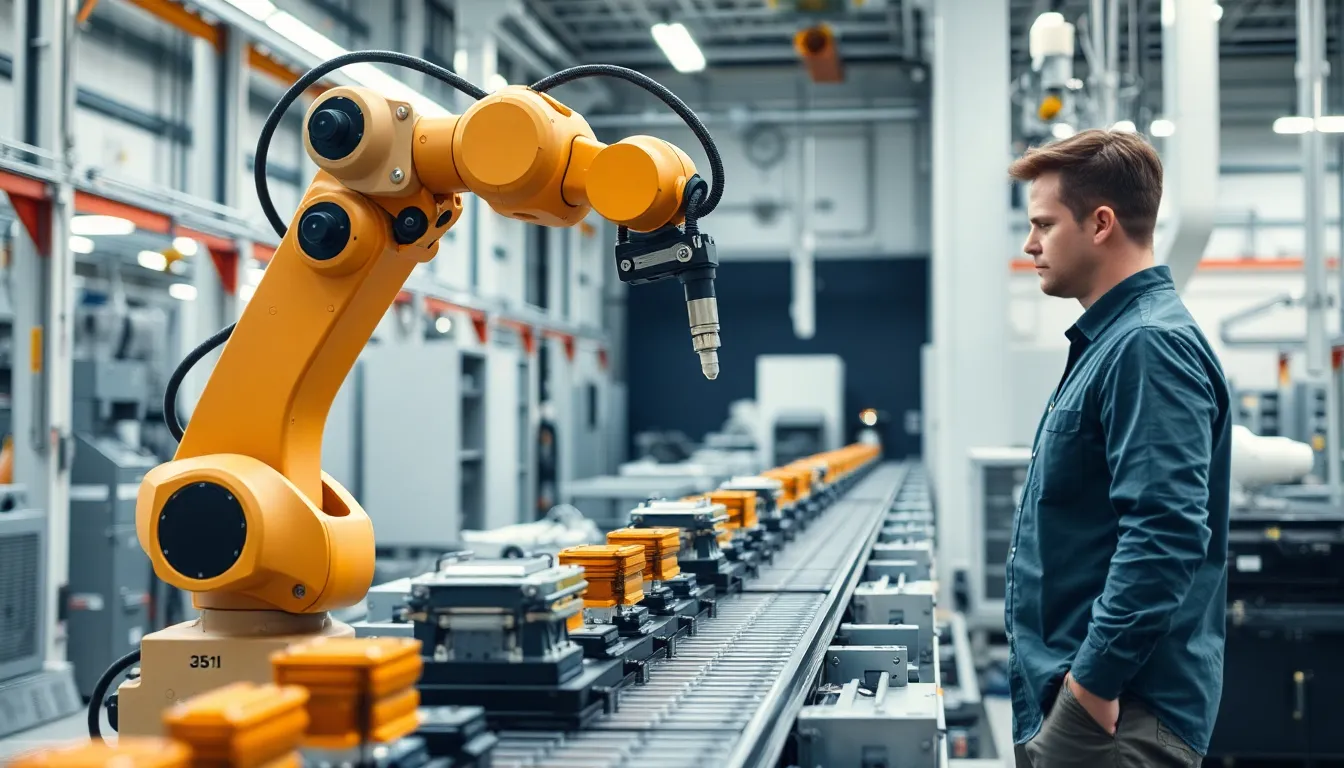

Robotic automation manufacturing integrates robotics into production processes, enhancing efficiency and accuracy. Robots manage repetitive tasks like assembly, welding, and painting, significantly reducing human labor costs. This technology revolutionizes workflows, allowing human workers to engage in more strategic roles, such as problem-solving and process improvement.

With robots operating at high speeds, productivity increases while maintaining quality standards. Data shows that companies adopting robotic automation experience up to a 30% boost in production efficiency. These machines operate constantly without breaks, leading to reduced downtime in manufacturing facilities. Besides efficiency, robots provide consistent precision, with discrepancies in product quality being minimized to less than 0.1%.

Cost reduction forms a crucial part of robotic automation’s appeal. Initial investment in robotic systems typically pays off within two to three years due to lower labor costs and fewer errors. This technological shift also allows manufacturers to adapt quickly to market changes, resulting in faster response times to consumer demand.

Adoption of robotics also enhances workplace safety. Dangerous tasks can be delegated to robots, reducing injury risk for human workers. This shift not only protects employees but also aligns with regulatory expectations in many industries.

Overall, robotic automation manufacturing serves as a pivotal advancement for modern manufacturing. It’s clear that as more companies embrace this technology, the landscape of the manufacturing industry continues to evolve, highlighting the continuous interplay between human capability and robotic efficiency.

Benefits of Robotic Automation

Robotic automation offers several advantages that transform manufacturing processes significantly, optimizing both labor and production.

Increased Efficiency

Production lines equipped with robotic systems see productivity boost by up to 30%. Machines operate continuously, ensuring minimal downtime during operations. Robots excel at repetitive tasks such as assembly, welding, and painting, allowing them to maintain high output levels. Workers can then focus on task management and strategy rather than manual labor. Enhanced consistency in quality results from robots performing tasks with precision and speed. Additionally, integrating robots into workflows streamlines processes and accelerates production cycles, effectively meeting market demands.

Cost Savings

Implementing robotic automation leads to substantial savings for manufacturers. Initial investment generally pays off within two to three years due to reduced labor costs and fewer errors. Robots can handle tasks that would require multiple workers, decreasing overall workforce size. Increased efficiency translates to higher production rates, allowing companies to maximize output while minimizing overhead. Long-term operational costs decline as machines maintain consistent performance. Companies adopting automation report lower material waste, further contributing to cost efficiency.

Key Technologies in Robotic Automation

Robotic automation relies on advanced technologies to enhance efficiency in manufacturing processes. The interplay of various systems empowers factories to optimize outputs.

Industrial Robots

Industrial robots form the backbone of robotic automation in manufacturing. These machines handle tasks such as assembly, welding, and painting with high precision. Equipped with sensors, industrial robots detect and respond to changes in their environment, ensuring consistent quality. They operate continuously, which minimizes downtime and maximizes productivity. Data indicates integration of industrial robots can lead to a 30% increase in production efficiency. Companies leveraging these systems often experience a rapid return on investment within two to three years, thanks to reduced labor costs and fewer errors. Worker safety improves too as robots take over hazardous tasks, allowing employees to focus on more strategic activities.

Artificial Intelligence Integration

Artificial intelligence (AI) integration significantly enhances the capabilities of robotic systems. AI algorithms allow robots to learn from past experiences and adapt their actions accordingly. When AI is applied, robots can analyze large datasets to optimize operations and predict maintenance needs. This reduces the likelihood of mechanical failures and enhances overall system reliability. Companies that incorporate AI-enabled robots report higher productivity levels and better decision-making processes. The synergy between AI and robotics leads to greater flexibility in production lines, enabling manufacturers to respond swiftly to market demands. Implementing AI-driven robotic solutions often results in increased operational efficiency and sustained competitive advantages.

Challenges in Robotic Automation Manufacturing

Robotic automation manufacturing presents several challenges that companies must address.

Workforce Adaptation

Adapting to robotic automation requires a shift in workforce dynamics. Employees may feel uncertainty regarding job security as machines take over repetitive tasks. Training programs help workers acquire new skills necessary for managing and collaborating with robotic systems. Companies with strong training initiatives foster a culture of adaptability. Successful training ensures that workers transition into more strategic roles, leading to enhanced job satisfaction. Developing a clear communication strategy also plays a vital role in easing employee concerns. By involving employees in the automation process, organizations can boost morale and engagement.

Initial Investment Costs

Initial investment costs for robotic automation can be significant. Expenses include purchasing robotic systems, installation, and ongoing maintenance. While upfront costs may seem daunting, many companies experience a return on investment within two to three years. Cost savings emerge from reduced labor expenses and increased production efficiency. Data shows organizations can see production efficiency increases of up to 30%, which offsets initial spending. Furthermore, budgeting for automation projects involves careful planning to avoid unexpected expenses that can hinder implementation. Financing options are available, making it feasible for companies to invest in automation despite high initial costs.

Future Trends in Robotic Automation

Robotic automation continues advancing, with innovations shaping its trajectory.

Advancements in AI and Robotics

AI plays a pivotal role in the evolution of robotics. Companies integrate machine learning algorithms into robotic systems, which equips them with the ability to adapt to new tasks over time. Enhanced sensors and vision technologies provide robots with real-time data, enabling them to respond to changes in their environment. This adaptability leads to improved operational efficiency, with reports showing production increases up to 30%. As AI capabilities expand, automation systems become more intelligent, allowing manufacturers to optimize processes effectively and streamline operations.

Sustainability and Eco-Friendly Practices

Sustainability has gained significant attention in manufacturing with the rise of robotic automation. Robots contribute to eco-friendly practices by reducing material waste and improving energy efficiency during production. Precision in tasks minimizes errors, leading to lower resource consumption. Many manufacturers are now adopting robotic systems to enhance their sustainability goals, seeing reductions in carbon footprints as a result. By choosing energy-efficient robots and optimizing production schedules, companies can achieve both operational goals and environmental sustainability, aligning their strategies with global initiatives.

Conclusion

Robotic automation is reshaping the manufacturing landscape by enhancing efficiency and precision while minimizing operational costs. As companies increasingly adopt this technology, they’re not only boosting productivity but also improving workplace safety. The integration of AI and advanced robotics paves the way for a future where machines and humans collaborate effectively, driving innovation and strategic growth.

While challenges like workforce adaptation and initial investment costs exist, the long-term benefits far outweigh these hurdles. Embracing robotic automation positions manufacturers to respond swiftly to market demands and align with sustainability goals. This transformative shift is not just about replacing labor; it’s about redefining the manufacturing process for a more efficient and competitive future.